Tig Welding Sheet Metal

MIG welding is one of the most appropriate methods used for sheet metal. Ditch a 18-inch tungsten electrode for something much smaller like 116-inch tungsten.

Tig Welding Sheet Metal How To Get The Best Results With Our 11 Top Tips Rate My Welder

Tig Welding Sheet Metal How To Get The Best Results With Our 11 Top Tips Rate My Welder

TIG welding sheet metal.

Tig welding sheet metal. BUY TIG 200 DIGITAL. Eastwood - YouTube. Using Tungsten to Weld Mild Steel So weve mentioned tungsten often above and now wed like to break it down a bit so that you understand why Tungsten works so well when welding mild steel.

If you are welding sheet metal for aircraft applications or for any other that you can think of consider the following TIG welding tips to ensure that you get the high quality work that is. In this video Matt goes over three tips for TIG welding sheet metal that will help you get the best results. To weld sheet metal with solid wires use electrode positive EP or reverse polarity.

In this welding sheet metal video what is meant by invisible weld is a tig weld that is ground flat planished with a dolly and auto body tool and then fine sanded so that it looks like shiny bright metal and it is not obvious where the weld is. In order to learn how to tig weld first of all you want to set up a machine and its connected parts such as torch and gas plus have on hand a filler rod for whatever metal you will be like to weld. Ad High Performance Wide Range Structural Adhesives Bonding Plastic and Metal.

In such work TIG welders usually use weld sheet metal. Other sheet metal applications eg stainless steel in food service typically call for a size 7 TIG cup. Dont attempt to weld thin materials like sheet metal with flux-cored wires which put more heat into the base metal.

Safe Trading Welding Machine Tig on Leading B2B Platform. The best two electrodes for welding auto body sheet metal is either ceriated tungsten or thoriated tungsten. MIG Welding for Sheet Metal.

This method is favorable as it leaves room for beginners to practice and get better. Safe Trading Welding Machine Tig on Leading B2B Platform. TIG welding has so many applications.

Ad Quality Welding Machine Tig with Competitive Price. Namely it leaves you some room for error that can be fixed with experience or by using some tips and tricks. One of the most common is in the aviation and airline industries.

Forget the larger 18-inch tungsten electrode and use a smaller one. For welding sheet metal in aerospace applications use a 15 cup 1516-inch diameter. The tig welding process can be generally utilized to weld aluminum steel brass copper bronze gold nickel alloy and stainless steel and more.

Ad High Performance Wide Range Structural Adhesives Bonding Plastic and Metal. We find TIG welding often used for welding critical joints welding a variety of metals including mild steel and TIG welding also works well for small metal areas. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators.

How to Weld Auto Body Sheet Metal With a TIG Welder. Ad Quality Welding Machine Tig with Competitive Price.

Tig Butt Welding Thin Sheet Steel Car Bodywork Getting Started Part 3 Tips And Tricks 41 R Tech Youtube

Tig Butt Welding Thin Sheet Steel Car Bodywork Getting Started Part 3 Tips And Tricks 41 R Tech Youtube

Tig Welding Thin Sheet Metal Settings Youtube

Tig Welding Thin Sheet Metal Settings Youtube

Getting Started With Tig Welding Yeswelder

Getting Started With Tig Welding Yeswelder

First Time Tig Welding Two Pieces Of Sheet Metal Together Can I Get Some Constructive Criticism Welding

Tig Welding Aluminum Fabrication Sheet Metal Forming Round Hole To Rectangle Hole Transition Youtube

Tig Welding Aluminum Fabrication Sheet Metal Forming Round Hole To Rectangle Hole Transition Youtube

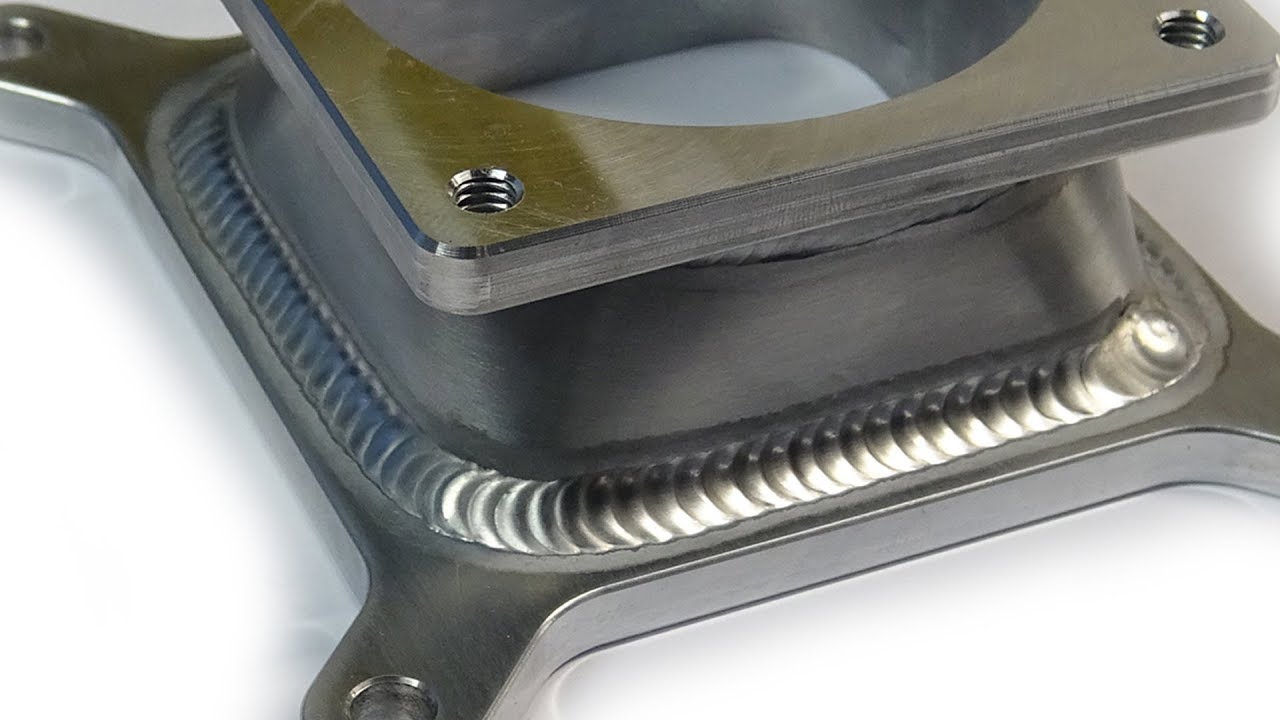

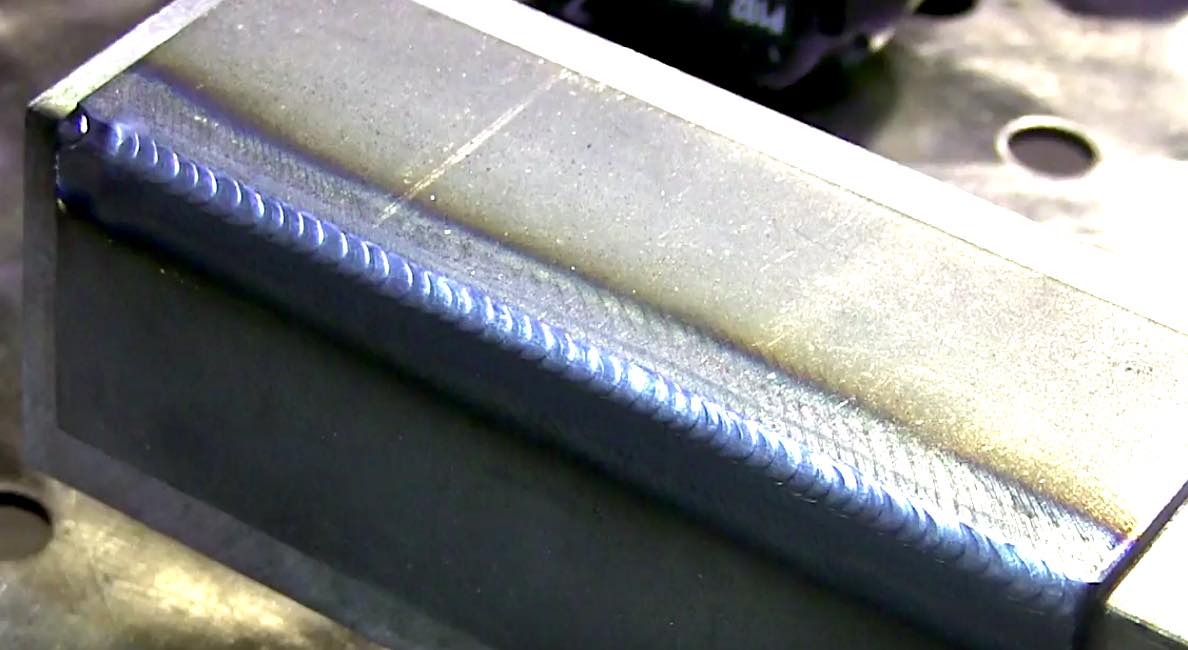

Tig Welding Outside Corner Joints Cold Rolled Steel

Tig Welding Outside Corner Joints Cold Rolled Steel

Stainless Sheet Metal Tig Weld Welding

Stainless Sheet Metal Tig Weld Welding

China Tig Mig Welding With Precision Sheet Metal Fabrication China Welding Parts Metal Welding Parts

China Tig Mig Welding With Precision Sheet Metal Fabrication China Welding Parts Metal Welding Parts

Tips For Welding Sheet Metal With Mig Or Tig

Tips For Welding Sheet Metal With Mig Or Tig

Butt Welding Basics Using Mig And Tig Welders

Butt Welding Basics Using Mig And Tig Welders

Tig Welding 1 6mm Stainless Fillets Viewer Request Youtube

Tig Welding 1 6mm Stainless Fillets Viewer Request Youtube

Tips For Welding Sheet Metal With Mig Or Tig

Tips For Welding Sheet Metal With Mig Or Tig

Tips For Welding Sheet Metal With Mig Or Tig

Tips For Welding Sheet Metal With Mig Or Tig

Comments

Post a Comment